Flow Bench

SKU:

Weight: 8500 g

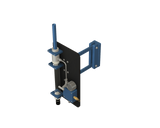

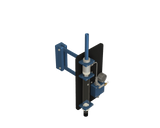

This flow bench has been designed to be used in combination with our Adjustable Bench Air Supply and our Analogue Advanced Set-Up Kit (-5-0-5 differential pressure gauge option) or Digital Advanced Set-Up Kit (-5-0-5 differential pressure gauge option). This combination will create a versatile powerhouse in testing capability for your shop. Our goal was to design a bench that's able to:

- accurately and repeatedly measure cracking effort

- perform manufacturers prescribed flow test

This panel has to be wall mounted and is adjustable in height to ensure 'ideal eye height' conditions for the user to prevent parallax error readings. A minimum amount of installation and assembly will be required.

The flow meter has a range of 0-40 m3 / hour - this is equivalent to 666 l / min or 23.5 scfm -.

The flow bench has to be connected to a low pressure air supply (max 10 bar) which is independent of the regulator under test. This can be done using a standard LP scuba hose that connects to the flow bench. An adaptor is also included to convert the male side of the LP scuba hose (3/8" UNF) into a 1/4" NPT M fitting that can be plumbed into a low pressure air supply system. If required we also have a adaptor kit to convert the 1/4 NPT M into a 1/4 BSP M (SCT-1021).

The flow in the meter (i.o.w. the flow through the second stage under test) is initiated by operating the needle valve that drives the venturi generator creating suction on the second stage under test.

The flow bench is equipped with a valve block that holds the needle valve to operate the venturi generator, pressure gauge to monitor the supply pressure to the flow bench, inlet fitting and over pressure relief valve.

In combination with the instruments mentioned, the technician will be able to test and evaluate:

- static intermediate pressure under a variety of supply pressure conditions

- static cracking effort under a variety of supply pressure conditions (the use of the needle valve allows a gentle and accurate method to exactly determine the cracking effort, which will be repeatable and totally independent of the operator)

- manufacturers recommended flow tests (e.g. for the Aqualung Mikron: at a flow of 400 l / min, the inhalation effort should no exceed 15 mbar)

- evaluate dynamic inhalation effort at different flow conditions of the second stage under a variety of supply pressure conditions

- evaluate the effect of the second stage venturi assist at different flow conditions of the second stage under a variety of supply pressure conditions (the latter can assist the technician in tuning / setting up the technician adjustable venturi of second stages)

Unit comes complete with:

- wall fixing hardware

- hose to connect flow bench to differential pressure gauge

- adaptor to convert male side of standard LP scuba hose into 1/4" NPT M

- latex band seal to connect second stage

Overall dimension: 660 x 255 x 375 mm.

We Also Recommend